Sewer backflow, a latent menace in the fabric of urban living, imperils both property integrity and public health. As wastewater reverses its course, contaminating clean water supplies, the pivotal safeguard emerges the sewer backflow preventer. This article navigates through the intricacies of sewer backflow, shedding light on its risks and emphasizing the paramount role of a diligently maintained sewer backflow preventer in shielding our communities from potential disasters.

Table of Contents

What is Sewer Backflow?

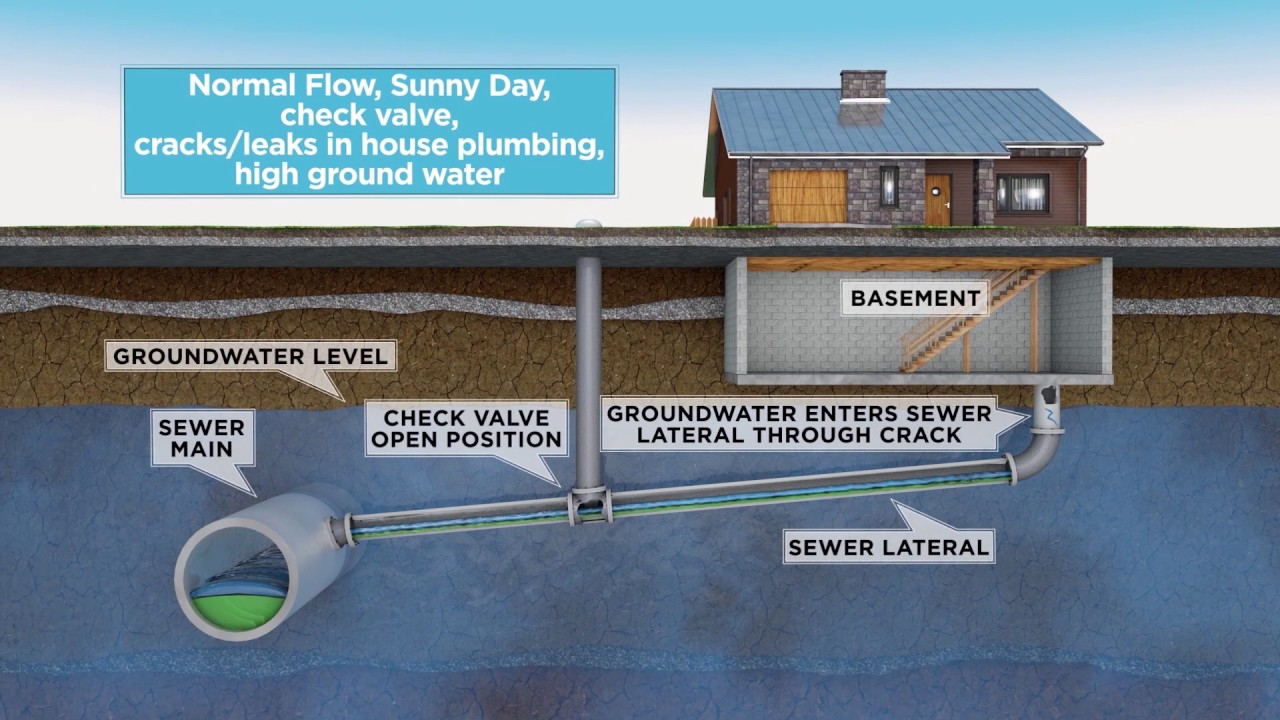

Sewer backflow refers to the unwanted reverse flow of wastewater from the sewer lines back into a building’s plumbing system. This typically occurs when there is a blockage or high pressure in the public sewer lines.

Normally, wastewater flows out of a building into the municipal sewer system. However, under certain conditions, that flow can be reversed, causing raw sewage to back up into the building’s plumbing. This is called a backflow event.

Sewer backflow allows contaminated water from the sewer lines to mix with the building’s clean water supply. This leads to something known as cross-connection contamination. When raw sewage enters the drinking water system, it can expose building occupants to bacteria, viruses, and other harmful contaminants.

Backflow occurs because of a difference in water pressure. When pressure builds up downstream in the public sewer lines, it can overcome the pressure in the building’s plumbing, forcing the wastewater to reverse direction. A clogged or overloaded public sewer main is often the culprit, but other factors like heavy rains, power outages, or flooding can also lead to backflow conditions.

The key point is that sewer backflow allows polluted water to infiltrate a clean water system. This serious public health hazard must be prevented through the use of backflow prevention devices.

Problems Caused by Sewer Backflow

Sewer backflow can lead to a number of serious issues if not addressed promptly. Here are some of the major problems that can arise:

- Health hazards from contaminated water – When sewage flows backward into the fresh water supply, it brings pathogens, bacteria, and viruses along with it. Exposure to contaminated water can lead to severe illnesses like hepatitis A, giardiasis, cryptosporidiosis, and other gastrointestinal diseases. Anyone using the water is at risk.

- Backflow of sewage into home/business – Raw sewage backing up into sinks, bathtubs, washing machines, and other fixtures is a disgusting and unsanitary problem. Sewage contains disease-causing bacteria and toxic gases like methane and hydrogen sulfide. Cleaning up alone is difficult and the stench can linger.

- Expensive repairs needed – Sewer backflow often causes plumbing and property damage. Floors, walls, and furnishings can be ruined. The sewer line itself may need cleaning or replacement. This type of repair work is unpleasant and costs thousands of dollars in many cases.

Preventing backflow is crucial for avoiding these types of issues. Installing a proper backflow prevention device can help stop contaminants from entering the water supply.

Types of Backflow Preventers

There are a few different types of backflow preventers that can be used depending on the specific plumbing situation:

Air Gap

An air gap is a physical separation between the water supply and the receiving vessel. This separation prevents backflow by ensuring an actual air gap between the water line and the vessel. Air gaps are typically used for devices like sinks and washing machines.

Reduced Pressure Zone (RPZ) Valve

An RPZ valve contains two spring-loaded check valves with a relief valve between them. The relief valve allows water to flow out if either check valve fails, ensuring constant pressure on the inlet side. These are installed near water meters and other points where the property’s plumbing connects to the public water system.

Double Check Valve (DCV)

A DCV contains two positive-sealing check valves placed between two tightly closing shut-off valves. There is no relief valve. DCVs provide protection against backpressure and backsiphonage but do not protect against backflow from pollution or contamination. They are used to isolate parts of plumbing systems.

Atmospheric Vacuum Breaker (AVB)

AVBs operate using a float check, atmospheric vent, and inlet and outlet shut-off valves. They allow air to enter the water line when there is a drop in pressure. AVBs are commonly installed on garden hoses and irrigation systems.

Pressure Vacuum Breaker (PVB)

PVBs are similar to AVBs but contain a spring-loaded check valve. They open when water pressure drops below atmospheric pressure, preventing backflow. PVBs are suitable for applications with constant pressure like commercial dishwashers.

Backflow preventers are installed in strategic locations to stop contaminated water from flowing backwards into the clean water supply. Choosing the right type for each application is key.

Installing a Backflow Preventer

Installing a backflow preventer requires careful planning and expertise. While it may seem like a DIY project, it’s highly recommended to hire a professional plumber for proper installation.

Permits Required

In most cases, you’ll need a permit from your local building department before installing a backflow preventer. The permit process ensures your backflow preventer meets local plumbing codes and regulations. Failing to obtain a permit can potentially void any warranties or insurance coverage.

Hire a Licensed Plumber

Unless you’re highly experienced with plumbing projects, install a backflow preventer yourself. There are many complexities involved, like correctly sizing and situating the device, modifying piping, and integrating with your existing plumbing. An experienced plumber has the expertise to ensure everything is done right the first time. They can also pull any required permits for you.

Proper Installation is Crucial

Improper installation of a backflow preventer can render it ineffective and essentially useless. Some key steps plumbers take to ensure proper functionality include:

- Selecting the appropriate type of backflow preventer based on your plumbing system and local regulations. The most common are atmospheric vacuum breakers, pressure vacuum breakers, double check valves, and reduced pressure zone devices.

- Situating the device in the correct location, usually between 10 to 20 feet of the water meter on the property side. This placement protects the main water supply.

- Proper sizing based on the water flow demand. Undersizing can cause insufficient water flow.

- Modifying piping configuration to integrate the backflow preventer.

- Proper support brackets and protection from freezing temperatures.

- Testing the device after installation to ensure it’s functioning and calibrated correctly.

By hiring a professional plumber, you can have peace of mind knowing your backflow preventer is installed correctly and protecting your water supply from contamination. Attempting a DIY installation often ends up being more costly in the long run if the device fails prematurely or doesn’t operate as intended.

Maintaining a Backflow Preventer

To keep your backflow preventer working properly for as long as possible, follow the manufacturer’s maintenance recommendations diligently. This usually involves:

- Annual inspections. Have a professional plumber inspect the backflow preventer annually to make sure it is still in good working order. They will check for any leaks, damage or potential issues.

- Annual cleaning. In addition to inspection, the backflow preventer valves and mechanisms should be cleaned once a year. Buildup of sediment and mineral deposits can impede functioning over time. Professional cleaning clears out any debris.

- Keeping valves & pipes clear. Make sure the valves and pipes leading to and from the backflow preventer are clear of any obstructions. Flush valves occasionally with water to prevent scale buildup. And don’t allow any landscaping, mulch or other materials to pile up around the valves where they enter the ground.

Following the manufacturer’s instructions for maintenance, along with annual professional inspections and cleaning, will keep your backflow preventer in tip-top shape. This ensures it continues preventing any potentially hazardous backflow over the lifespan of the plumbing system. Investing in regular upkeep avoids more costly repairs or replacement down the road.

Cost of a Backflow Preventer

The cost of a backflow preventer depends on a few factors, primarily the type of valve you need and whether you hire a plumber for installation and maintenance or do it yourself. Here’s a breakdown of typical costs:

Hardware Costs

The backflow preventer valve itself ranges from $100 on the low end for a basic hose bibb vacuum breaker, up to $500-800 for a commercial grade reduced pressure zone backflow preventer. More complex backflow preventers with control valves and test ports can cost $1,500 or more.

The average homeowner with minor backflow concerns can expect to pay around $150-300 for a basic backflow prevention valve.

Plumber Installation Charges

If you hire a professional plumber to install your backflow preventer, expect to pay $200-500 for labor, depending on the complexity of the job. Simple hose bibb vacuum breakers can be installed for $200-300, while installing a commercial grade backflow preventer under a home or building can run $400-500 with additional materials.

Always get multiple quotes when hiring any plumber. Backflow preventer installation costs can vary widely by region and individual plumber rates.

Annual Maintenance Fees

Backflow preventers require annual testing and maintenance to ensure they continue functioning properly. This involves opening/closing the valves, checking for leaks, and testing water pressure.

Most plumbers charge around $75-150 per year for backflow preventer testing and maintenance. This generally takes 30-60 minutes annually.

Some preventers like hose bibb vacuum breakers don’t require testing or maintenance. But for most, annual servicing is critical to avoid potential backflow incidents.

Backflow Prevention Without a Valve

While a backflow preventer valve is the most reliable method, there are some simple plumbing fixtures you can use to help prevent backflow:

- Dual check valves – These have two check valves installed on water outlets. They allow water to flow in one direction but prevent it from reversing back. Dual check valves can be installed on hose bibs and toilets.

- Air gap fittings – An air gap is a physical separation between the water outlet and the drainage system. These are commonly used for dishwashers, preventing dirty water from backing up.

- Sink and tub drain plugs – Keeping drains plugged when not in use creates an air gap that blocks backflow.

However, these plumbing fixture methods have limitations:

- They only protect individual fixtures, not the entire plumbing system. Backflow can still occur elsewhere.

- They are passive and rely on gravity, so very high flood water or pressure could still overwhelm them.

- Old or faulty valves may not work properly to stop backflow.

- They require vigilance in usage – people have to actively keep drains plugged when not in use.

So while helpful, fixture-only backflow prevention does not replace a professionally installed, maintained, and inspected backflow preventer valve. For full protection, a valve is recommended.

Signs of Sewer Backflow

Knowing the signs of sewer backflow can help you identify and address the issue before major damage is done. Here are some of the most common indicators that you may be experiencing backflow:

- Contaminated water smell/appearance – If your water starts to give off a rotten egg smell or you notice a change in color or cloudiness, sewage could be contaminating the water supply. Don’t use water from any fixture where you detect an abnormal smell or look.

- Low water pressure – A sudden, unexplained drop in water pressure can occur when sewage backs up and blocks the supply lines. Check your faucets and shower – if the flow seems weaker than usual, the plumbing may be obstructed.

- Gurgling sounds from drains – Listen for gurgling, burbling or slurping sounds coming from sinks, bathtubs or floor drains when not in use. These noises may indicate sewage and waste moving in the wrong direction through the pipes.

- Higher sewer gas smell in the home – Since contaminated water brings sewer gases with it, you may notice an increased stale or rotten egg-like odor inside if backflow is occurring. The smell may be especially bad around floor drains.

- Toilet bubbling or drainage issues – Sewage backflow can cause bubbling or drainage problems from toilets. If your toilet seems to flush slowly or bubble up during use, it could be a sign of blockages from backflow.

Any of these issues indicate you should call a plumber immediately to inspect for backflow and install a backflow preventer. Ignoring the signs could allow contaminated water to spread throughout your plumbing system, creating a serious health hazard. A professional can diagnose the issue and take steps to keep your water supply clean and safe.

What to Do if You Have Backflow

Sewer backflow is a serious issue that requires immediate attention. Here are the steps you should take if you suspect you are experiencing backflow in your plumbing system:

Stop Using Water Immediately

The first thing you should do if sewage is backing up into your sinks, tubs or toilets is to stop all water use in your home. Discontinue using any water source including faucets, showers and washing machines. Limiting water use will help prevent further backup and contamination of your water lines.

Call a Plumber to Inspect

Contact a licensed, professional plumber to come inspect your plumbing system. They will be able to diagnose the issue and determine if you do indeed have a backflow problem originating from the sewer line. The plumber can also advise you on the best solution, which is likely installation of a backflow prevention device.

Boil Water Advisory

Chances are the plumber will recommend boiling all water used for drinking, cooking, brushing teeth, etc. Backflow from a sewer line can introduce dangerous contaminants into your water supply that could make you sick. Boiling the water is an extra precaution to kill any bacteria or pathogens that may now be present in your pipes. Adhere to the boil order until plumbing repairs are made and tests show your water is safe again.

Taking these steps quickly can help resolve a backflow issue before it creates costly plumbing repairs or serious illness. A reputable plumber has the expertise to diagnose what is causing contaminated water to backflow into your home and rectify the problem.

Preventing Backflow Without a Plumber

Sewer backflow can potentially be prevented without installing a backflow prevention valve if you take proactive measures to maintain your plumbing system. Here are some tips:

Regularly maintain your plumbing – By keeping your drains and sewer lines clear of buildup and blockages, you reduce the risk of wastewater backing up. Use drain cleaners monthly and have a professional plumber snake your lines annually. Tree roots, grease, and debris in the pipes can all impede flow and contribute to backups.

https://drainservice.org/the-importance-of-regular-drain-maintenance/

Don’t pour fats, oils, or grease down drains – Fats, oils, and grease (FOGs) can congeal in pipes and cause major blockages that lead to backflow. Always collect food grease in containers and dispose in the garbage instead of the sink.

Be aware of cross-connections – Cross-connections between potable water and waste lines can cause backflow contamination. Ensure sprinkler systems, boilers, hoses, and other devices have proper backflow preventers installed. Don’t attach hoses or tubes to non-potable water sources.

Check sink, tub, and floor drains – Make sure all drains have functioning water traps to block sewer gas and odors. Pour water down unused drains monthly to keep traps full. Install positive flapper drain stops if missing.

Monitor for signs of backflow – Be on the lookout for indicators of backflow like gurgling drains, foul odors, discolored water, and backed up toilets or sinks. Address any issues immediately to avoid bigger problems.